Introduction

Hybrid Electric Vehicle (HEV) development demand more and more accurate simulation of Automotive systems to achieve quality-, reliability and cost-requirements.

Reliable vehicle operation depends on successful integration and verification of all drivetrain component interactions under varying operational and environmental conditions. Given the extraordinary complex nature of hardware and software controls in drivetrain design, engineers use Robust Design methods to characterize and verify the interaction of mechatronic systems. Saber’s comprehensive modeling, simulation, and analysis capabilities are applied to improve system performance, reduce cost, and maximize reliability of these critical systems.

Hybrid Electric Vehicle Feature Highlights

Due to the advantages of high energy efficiency and low environmental pollution, the hybrid electric vehicle gets a lot of attention in the automobile industry recently. Compared to the traditional car, the hybrid electric vehicle employs much more electronics technologies, the interactions between the electrical system and mechanical system becomes more frequent.

The overall system is much more complicate and it presents a great challenge to the automobile design engineer: how to simulate such a complicate mixed system to increase the reliability and robustness prior to the physical design?

As we know, most difficulties encountered during simulation of a complex system are :

I. The amount of simulation time is unacceptable. With an increase of system complexity, especially for the power switching system, the time step of transient simulation is determined by the switching frequency, it takes hours for a simulator to simulate the start up behavior of a switching power system.

II. Convergence problems. It is much more difficult for the simulator to find the solution when the system gets more complicated. With the flexibility of advanced modeling languages (MAST, VHDL-AMS) and top down design methodology, designers could simplify the system at different abstraction levels by focusing on different interested characteristics. Then the simulation speed can be improved by 30 times without losing the accuracy of overall system behavior.

Saber for Hybrid Electric Vehicles

This powerful software allows users to :

- Evaluate design architecture tradeoffs (parallel, serial, or complex topologies)

- Analyze power generation and distribution for motor drives and controls, regenerative braking, power assist, etc. Incorporate multi-domain effects at the system level – mechanical, electrical, thermal, and magnetics

- Design, test, and verify control strategies, power management, torque/speed coupling, and vehicle dynamics

- Specify and size HEV and EV powertrains and components (motors, controllers, and energy management)

- Enhance system safety and reliability using Robust Design methodologies, Worst Case Analysis, and Fault Analysis

Saber includes a broad collection of models and tools for simulating HEV systems:

- Motors (analytical and FEA-based models)

- Power devices – IGBTs, MOSFETs, BJTs

- Batteries, ultracapacitors, and charging systems

- Inverters, DC/DC converters, switches, speed controllers, capacitors

- Mechanical components

Example of HEV Design

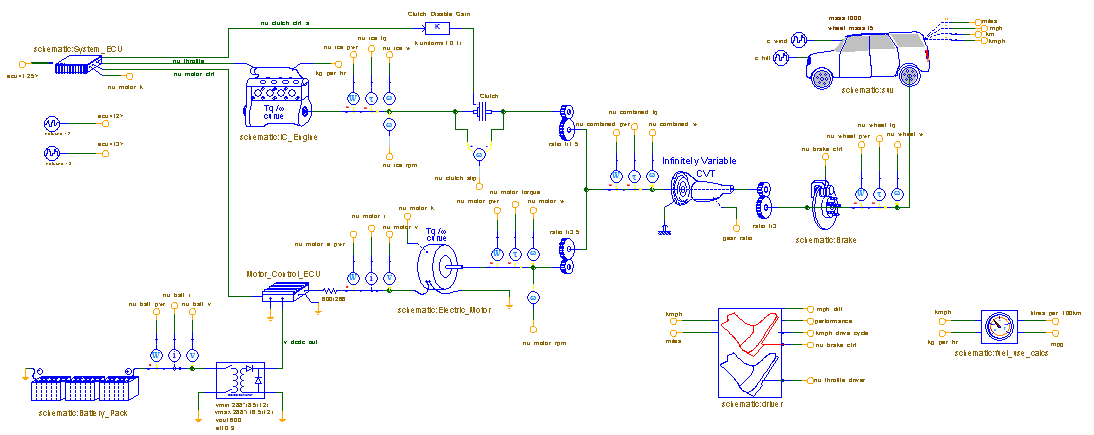

This example is a high-level HEV system design. The design contains hierarchical schematic models for typical hybrid electric vehicle designs, such as battery model, electric motor, internal combustion engine, transmission and ECUs, as well as hierarchical schematics for physical models, such as the brakes, vehicle mass and drag aspects. There are also driver inputs and a block that calculates fuel consumption and other interesting measurements. Any of these models could be replaced with a more detailed model for a more realistic design.

Description

The system ECU is a sophisticated control algorithm that controls the whole system and makes the complex technology transparent to the human driver. The IC Engine is allowed to run at its most efficient and least polluting point. The vehicle driver enjoys increased fuel economy, increased performance, and has decreased environmental impact. In this design, a simple, non-regenerative brake model is used. Regenerative braking could be included, with appropriate feedback loops and modifications to the ECUs, to simulate energy re-capture. Due to feedback through another ECU, various motor-generator combinations allow charging of onboard batteries when excess power is available from the IC engine.

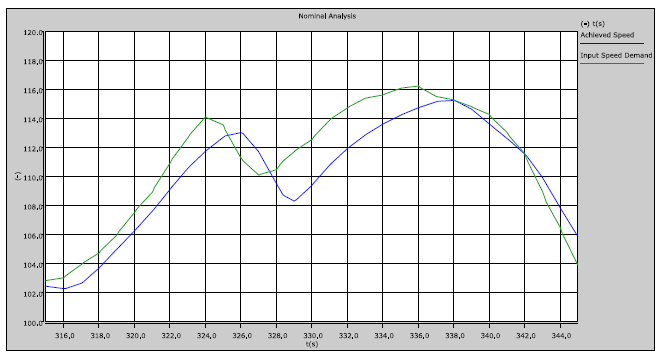

One of the main outputs to examine is the achieved speed, compared to the demanded speed. Several outputs are calculated in the SUV block, including kmph (the signal of interest), km, mph and miles.

Analyses

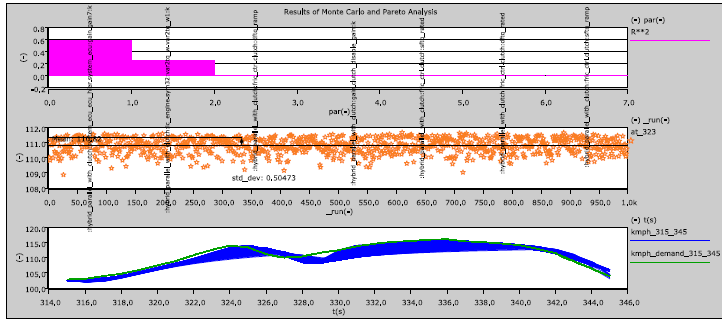

The above schematic can be used to explore nominal behavior, as well as running a Monte-Carlo analysis and subsequent statistical analyses, including a Pareto analysis, to determine which parameters affect the achieved speed the most.

Thanks to Pareto analysis, it is quite easy to identify the parameters that has most effect on the measurement. The results of Pareto analysis (in pink) shows that two parameters have most effect on the standard deviation and the parameters are gain (k) of gain7 component in System ECU hierarchical block and gain (k) of var2tq_w1 component in IC engine hierarchical block.

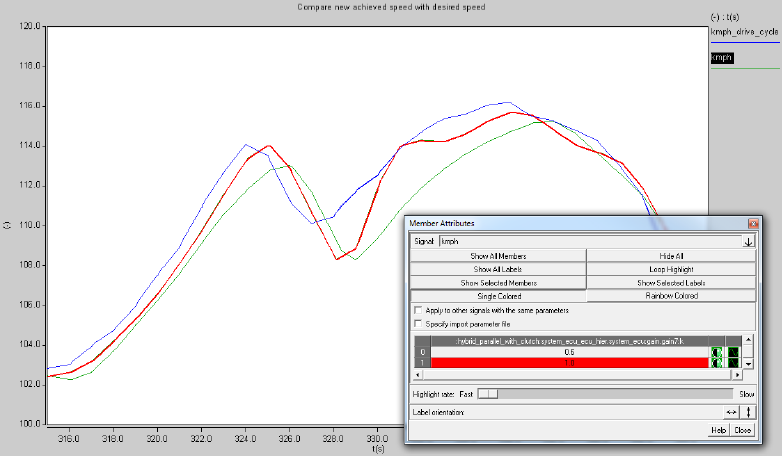

So, after some simulations, setting gain (k) of gain7 component to 1.0 and tightening tolerance of gain (k) of var2tq_w1, the variation in achieved speed has been reduced. Therefore, the achieved speed is more controlled and close to desired speed.

In conclusion

A typical HEV powertrain design in a high level has been implemented. Of course the models could be replaced with a more detailed model for a more realistic design. In the design, achieved and desired speed is compared and studied. Achieved speed showed some deviation from desired speed in one particular region of drive cycle. The region of interest was carefully investigated and methods were adopted to reduce the variation. Complex analysis like Monte Carlo followed by Pareto were carried out easily using advanced features of experiment editor in SaberRD. As a result of analysis conducted, variation in achieved speed was reduced and brought close to desired speed.

By using Saber, engineers who design HEV will :

- Improve the complete design by analyzing at the system, sub-system, or vehicle level

- Save time and eliminate errors by using models from an industry proven components library

- Optimize cost, performance, and reliability with advanced stress, sensitivity, and statistical analyses

- Model complete mechatronic systems using industry standard VHDL-AMS & MAST languages

- Test the complete system earlier with hardware/software co-simulation

- Increase analysis throughput with distributed simulations across multiple CPU