Optimization of the cable configuration using ampacity analysis

Power systems transmit electrical power from one point to another using cables and lines. As every conductor has a resistance, the power transmission cannot be achieved without power losses. Moreover, the magnetic interactions create eddy currents in every metallic part. This eddy currents produce heat. Most of these power losses are converted into heat. This increases conductor temperature.

Concerning cables, electrical insulation and soil decrease cable ability to exhaust heat, which lead to higher temperature risings. This can lead to structural issues in the cables. Besides, the temperature rising changes properties of every piece of equipment. For example, the hotter a cable is, the higher its core resistance is. An excessive temperature leads to failures of some pieces of equipment. Hence, temperature in cables is a major question and the anticipation of cables overheating is very important during the power system design.

Cable temperature is depending on various factors such as the cables themselves (material, diameter, layers, …), their configuration (trefoil, in flat, number of conductors) or external variable (season, load to transmit, …). This way, knowing the cable overheating in different conditions allows engineers to optimize their design and to get constraints on their system.

Our consulting service will help you to have a perfect knowledge of your cable system. Our long experience in cable overheating analysis will allow you to:

- Get the precise heat distribution in and around your cables, considering the cable models, their configuration and the environment conditions,

- Optimize your cable configuration to get the best ampacity regarding a specific case,

- Get the cable heat profile in time domain to consider the load time cycle (day/night, week, high and low consumption…)

|

Modelling

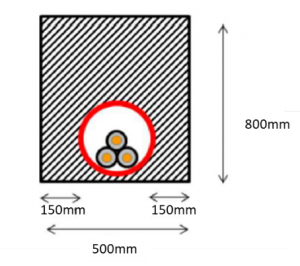

To estimate ampacity, it is necessary to model correctly the cable and its environment. Our consulting team can carry the modelling of both cable and its environment. Our modelling takes into account conductors and fill materials and geometry to reproduce accurately the real conditions cables will be in. A wide range of cables types (single-core, three-core…), disposals (buried, underground ducts…) and sheath bonding arrangements can be integrated to our modelling. |

|

|

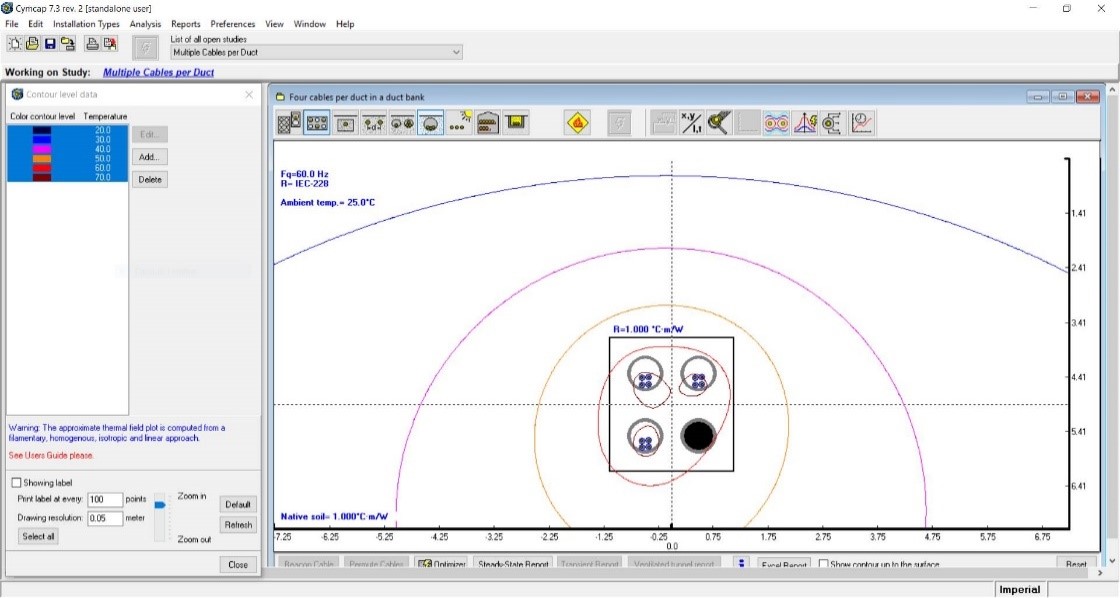

Ampacity studies

Depending on your needs, Powersys consulting team can realize ampacity studies of several types. From cables disposal and current that circulates through them, Powersys Engineering team is able to determine the cables and environment steady-state temperatures. Our consulting team uses finite-element calculations. Thanks to this method, we can provide you very accurate analyses of temperatures around you cables. Then, Powersys can do the reverse process and determine the maximum current (ampacity) that a cable can carry without exceeding a stated temperature. Our team can provide ampacity studies results as:

Various configurations are possible (buried cables, cables in duct, in tunnel, overhead cables…). |

|

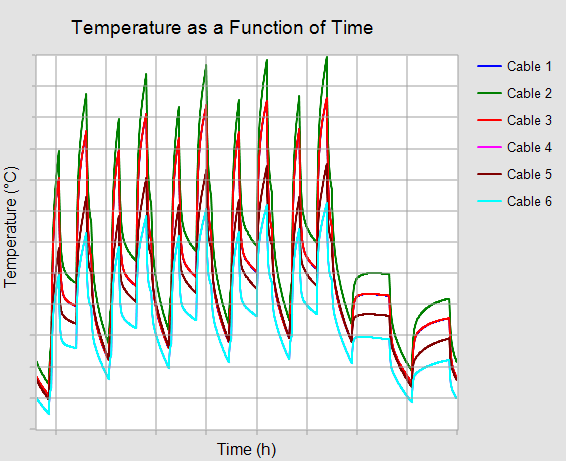

Transient temperature

Powersys Engineering team proposes to determine, based on current intensity time profiles, the evolution of cables and environment temperatures in time. We also propose to determine, for stated time and temperature, the ampacity of cables. |

We provide you with the best suited solutions to answer your requirements, objectives and projects in a comprehensive array of engineering services. The success of your projects is our main goal.