Validation of an electronic component through standard transient simulations

Powersys was contacted by an automotive supplier to determine the robustness of a device they produce for a car manufacturer. This end client wants every pieces of equipment they use to be tested to ensure it can endure some standard voltage transients.

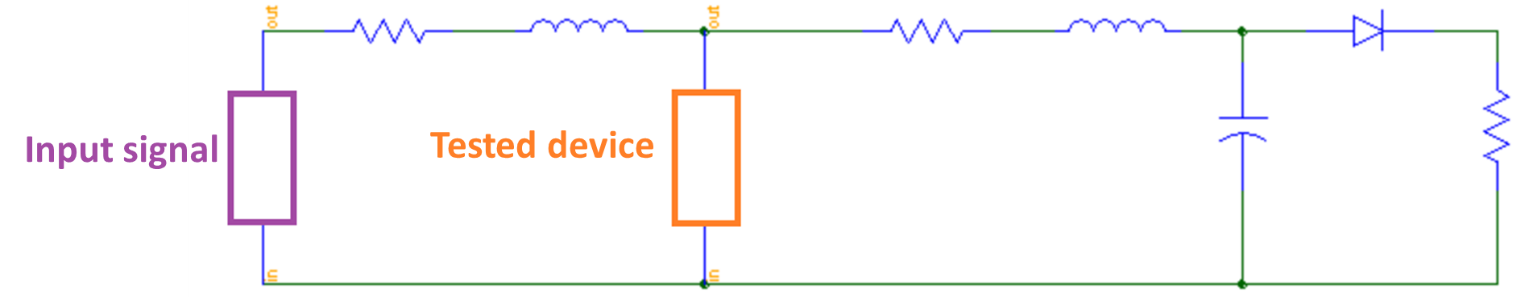

The device and the test circuit are modelled:

The transient that had to be tested is quite short and depends a lot of each device parameter. So, Powersys Consulting Team built an accurate model.The model contained components (such as diodes) for which Powersys built advanced models to consider some specific behaviors (direct and reverse curve, capacitive effect, transit time and temperature dependence for the diode).

Some component models were available in data files. Powersys decided to transcript these files by editing subcircuits to emulate accurately their behavior.

Concerning the rest of the components, spice models were available. Powersys Consulting team transcribed these spice files into HDL (hardware description language) to obtain models with great accuracy. The end client had also provided spice models that described transient events. Powersys uses the same method to model them exactly.

Powersys strictly respects the validation procedure that end client had required and validated the global system.

|

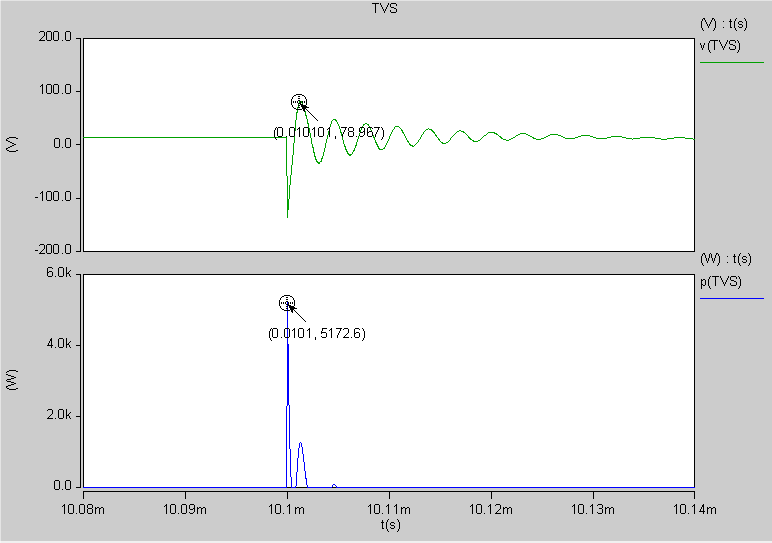

The reaction to standard transients is tested: To have an extensive knowledge of the device behavior, Powersys Engineering Team simulated the occurrence transients on a wide scale of temperature. |

|

|

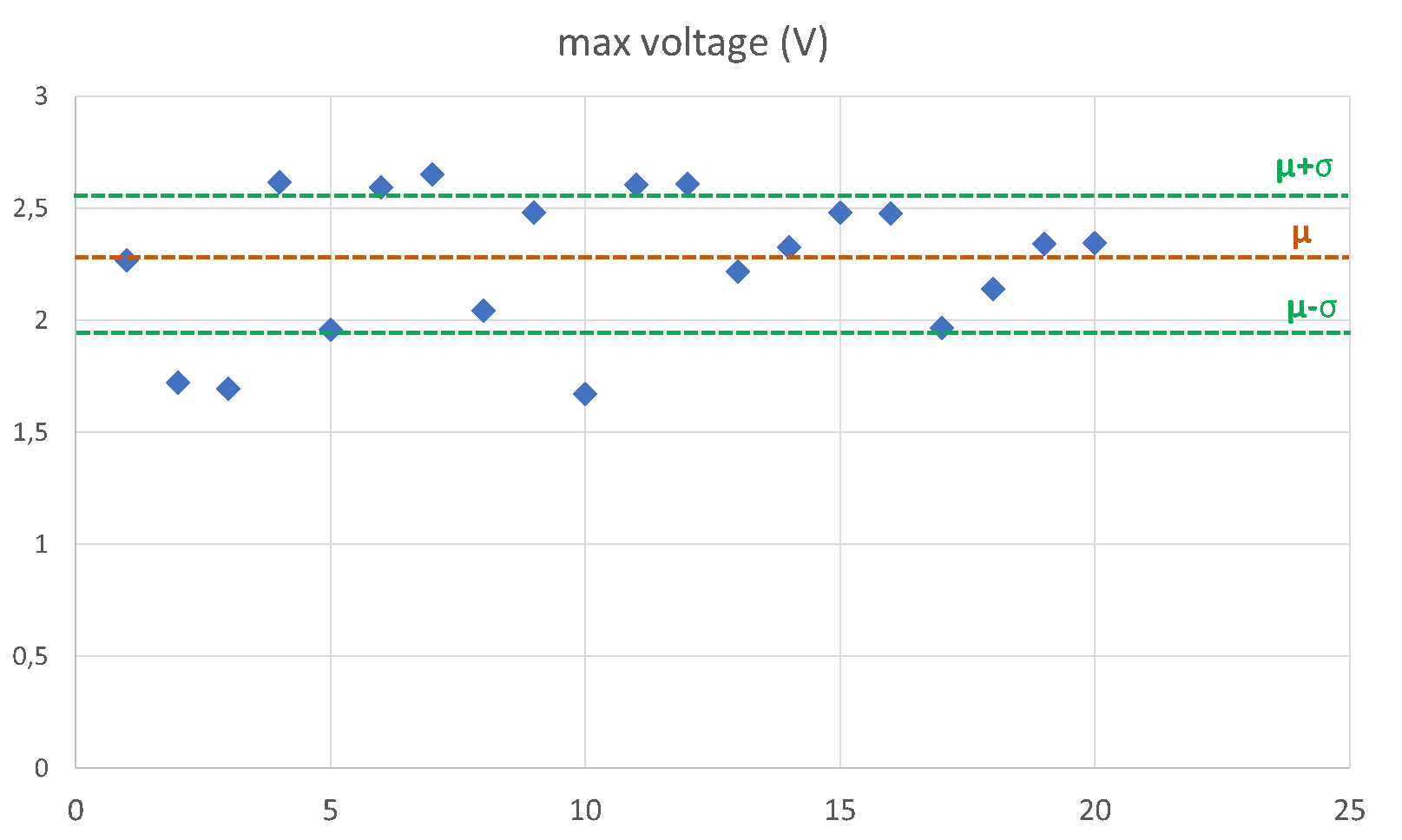

Statistical analyses and robust design were executed: As we knew a good power electronics system must be able to endure every issue that could appear during its operation, we performed functional safety analyses, which consists in simulating the occurrence of various issues one by one and observing the resulting transients.We launched multiple analyses varying every parameter of every device in the circuit and observed the transient voltages and currents. Thanks to that, we helped our client in the designing process by telling which parameters were the most impacting. Powersys Engineering team also considered statistical uncertainties of the devices used in the electronic card. With a Monte-carlo analysis, we determined the statistic repartition of transient signals characteristics such as maximum value or speed. We also carried a worst-case analysis to determine the most pessimistic case. |