Find everything you need on our resources center, product brochures, presentations, papers and more.

Login or create an account and get full access

In this presentation a workflow is presented for multi-objective, multi-constraint optimization calculations. A large design space is needed to be explored to reach an optimal solution.

By avoiding geometry breakdown, a trouble that occurs during dimensional optimization, 100% of the number of individuals required for optimization calculations can now be obtained. Range Finder can be used to ensure that the established geometry required for optimization calculations is obtained while properly adjusting the dimensional range

By avoiding geometry breakdown, a trouble that occurs during dimensional optimization, 100% of the number of individuals required for optimization calculations can now be obtained. Range Finder can be used to ensure that the established geometry required for optimization calculations is obtained while properly adjusting the dimensional range.

Lubricant distribution predictions and churning loss simulations are typically not an early part of a transmission design process. This is because CFD analysis requires significant modelling and simulation time along with high levels of expertise.This means that problems are typically found late in the design and development process when it is much more expensive to resolve issues.

In this webinar, we are going to show how effectively do simulation in PSIM Software with the behavior model of a PMSM, created in JMAG software and analyze machine parameters such as Voltage, Current, Torque, Copperlosses and Ironlosses.

The presentation aims at providing an overview on typical optimization topics in the E-machine design process and introduces the methods currently in use. In addition, some JMAG-specific features that are used within the workflow are highlighted and discussed.

The limiting accuracies of state-of-the-art 2D simulations do not always meet the expected precision for performance predictions and auxiliary effects. In this contribution we will present modern approaches and design flows to face the most demanding FEA simulation tasks.

This presentation overviews IPM machines for electric vehicles, with reference to novel magnetic-field-shifting techniques for enhancing the torque in a new class of IPM machines.

The electrical machine design process using both the parametric and topology optimization methods for e-mobility application. The parametric optimization is used toward meeting performance requirements while keeping the product sustainability and efficiency targets, however, topology optimization is mainly employed to address NVH aspects of the designed electrical machine.

In JMAG-Designer Ver.21.0, creating models for control, circuits, and windings has become easier than ever, and the calculation speed and processing speed of operations have been increased to improve the efficiency of analysis work.

In this webinar, Adarsh Viji Elango from ESTECO, and Sainan Xue and Dheeraj Bobba from Powersys are going to present the design process of a highly constrained multi-dimensional rotor geometry for an electric traction machine using principles of multi-objective optimization. In this solution methodology, the rotor design is evaluated by optimizing the tradeoff between...

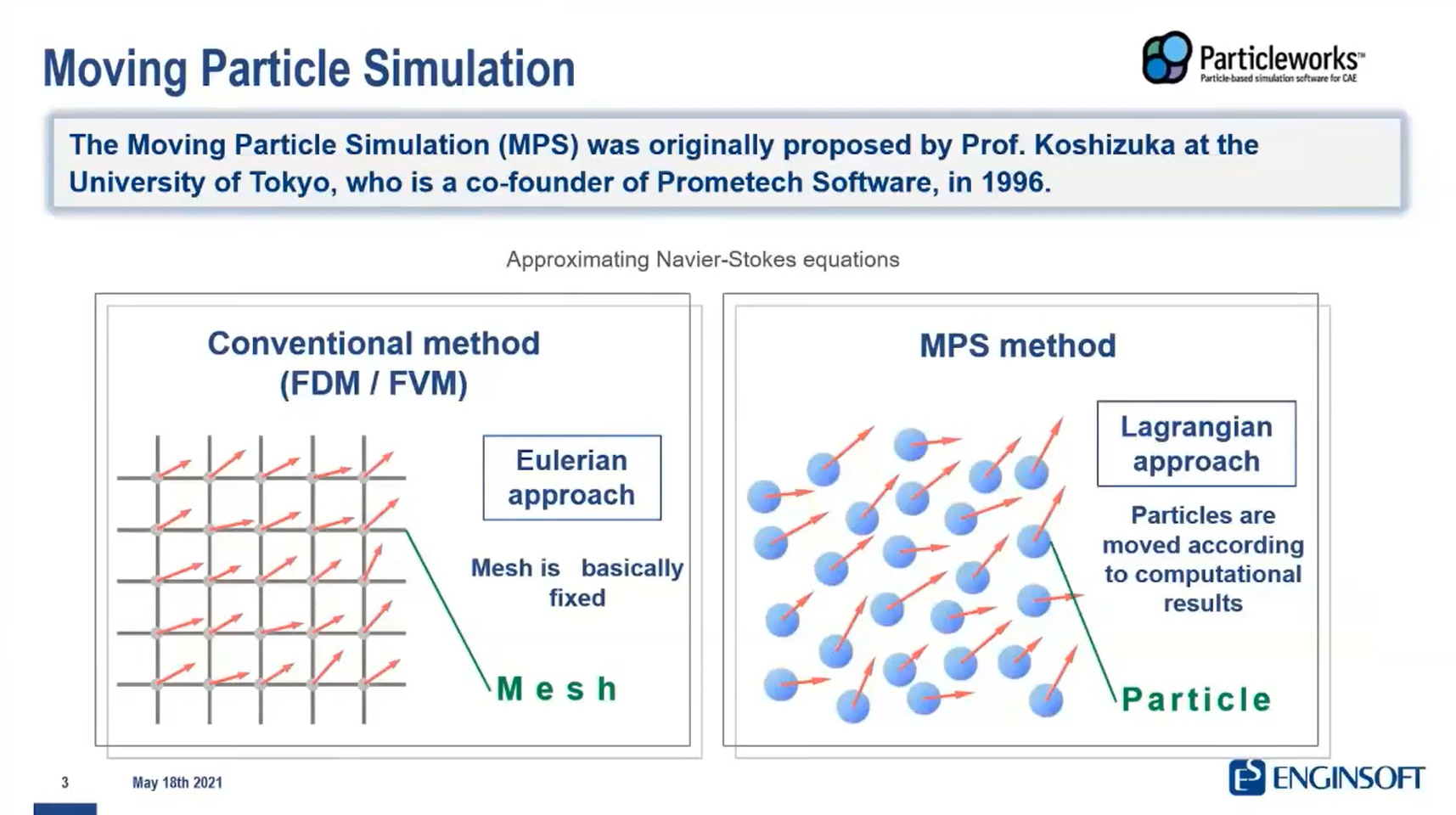

Particleworks is a meshless, CFD software for the simulation of liquid flows based on MPS. With an increase of demand for hybrid and electric traction in the automotive market, the development of e-drives requires a significant increase in power density while reducing costs.

In this webinar EnginSoft welcomes Tobias Moll, research assistant from the Institute for combustion engines at RWTH Aachen University. He will provide us with industry insights about the role of simulation for efficiency, lubrication and heat management for transmissions with Integrated electrical machines.

Oil jets are widely used in high performance and racing engines in order to prevent the piston from overheating and protecting the engine from serious damage. The oil flowing across the underside of the piston helps cooling off the component, so the heat is transferred to the oil.